Foundry Industry

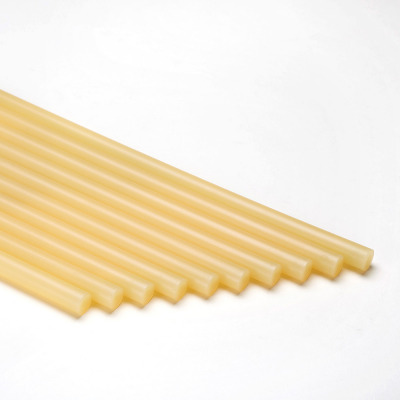

TECHSiL offer an innovative range of hot melt adhesives for core assembly, ideal for use where sand cores are fixed together and assembled. Techsil's FOUNDRY-TEC® range of hot melt adhesives bond instantly and more efficiently without any wait time or use of solvents compared to other fixing systems such as water-based glues or screws.

Advantages of FOUNDRY-TEC® hotmelts over other fixing systems such as water-based glues:

Other benefits include improved accuracy and productivity and a reduction of scrap. These hot melts can be used for both cold and hot processes in sand foundries. Use on cold processes such as 'Coldbox, Alpha Set and Beta Self," allow immediate assembly whereas use on hot processes such as 'Hotbox, Warm Box and Shelf require a cool off period before being assembled.

The range includes long, medium and short open times and variable viscosities for more accurate beading or spraying.

TECHSiL also supply hand-held hot melt glue guns to suit, which connect to an electrical supply. The adhesive from the cartridge melts inside the gun chamber and once melted can be extruded directly onto the sand core.

- Increased production

- Risk of gassing is reduced

- No solvents

- Fast speed of set

- No waiting

- No shelf life

- Reduced storage

- Cost effective

Power Adhesives Hot Melt Specialists

foundrytec®

tecbond®

tec™

Foundry Product Ranges

Connecting industries worldwide with

innovative bonding solutions

Find a Specialist

Andy Sabine

TECHNICAL SALES MANAGER

andy.sabine@techsil.co.uk

+44 (0)7792 531341

Slater Jinkinson

SALES DIRECTOR

slater.jinkinson@techsil.co.uk

+44 (0)7765 668959

Do you have an enquiry?

Reach out to our Technical Team for expert assistance regarding your foundry application or problem, and book a complimentary consultation.

technical@techsil.co.uk | +44 (0) 1789 774 244

Resource Centre

Visit our Resource Centre and discover a comprehensive collection of informative videos, white papers, and technical guides that examine our innovative approach to the Foundry industry.