LIGHTING & LED INDUSTRY

When designing LED luminaires and modules, design engineers rely on advanced liquid materials to provide environmental protection, enhance thermal performance, and extend service life. These materials play a critical role in maintaining light output, colour stability, and long-term reliability by protecting sensitive components and managing heat generated at the diode level.

TECHSiL offers a comprehensive range of high-performance materials specifically developed for LED assembly, bonding, sealing, and protection. Our solutions provide effective thermal management to dissipate heat away from LEDs, while also safeguarding assemblies against harsh environmental conditions such as moisture ingress, vibration, and thermal shock.

Engineered for use in demanding LED applications, TECHSiL materials exhibit excellent UV stability and carefully controlled optical properties, including optimised refractive indices where required. This ensures consistent performance across a wide range of lighting designs, from indoor architectural luminaires to outdoor and industrial LED systems.

Contact our Technical Team today and book a complimentary consultation.

What are LEDs?

LEDs, or light-emitting diodes, are semiconductor light sources that are rapidly replacing traditional lighting technologies due to their significantly lower energy consumption and extended service life. Available in a wide range of colours and form factors, LEDs are now widely used across both industrial and consumer applications.

As a more sustainable and cost-effective lighting solution, LEDs are increasingly adopted across industries including automotive, aerospace, appliances, marine, commercial, and architectural lighting. However, despite their efficiency, LEDs generate concentrated heat at the junction level, which can create safety and reliability challenges if not managed correctly.

In addition, LED assemblies are typically compact and lightweight, placing greater demands on materials used for PCB protection, environmental sealing, vibration damping, thermal management, and optically clear bonding. These challenges require carefully selected materials that protect sensitive electronics without compromising light performance or long-term reliability.

TECHSiL offers a comprehensive range of advanced adhesive and silicone solutions designed to address these challenges across the full spectrum of LED lighting applications. From thermal management and environmental protection to optical bonding and mechanical stability, TECHSiL materials help LED manufacturers deliver reliable, high-performance lighting systems.

LED & Lighting Applications:

- Automotive headlights and displays

- Security and flood lighting

- Electronics and appliances

- Commercial lighting

- Aerospace

- Underwater and oceanic lighting

- Industrial and hazard area lighting

- Outdoor/street and infastructure lighting

- Consumer and domestic lighting

- Signage and display lighting

- Horticultural and agricultural lighting

- Medical and healthcare lighting

- Transportation lighting (Rail, Aviation, Marine)

- Smart buildings and control integration

LED & Lighting Industry Challenges

As LEDs are used across varied industries, numerous challenges must be considered during manufacturing, assembly, and end use, including:

- Long term extreme temperature and UV exposure

- Uniform and efficient light distribution

- Weight reduction and miniaturisation

- Physical shock and scratch protection

- Weathering, corrosion, and water exposure in outdoor or marine applications

- Loosening from constant vibration in automotive applications

- Aesthetic concerns with traditional fastenings

- Electrical and consumer safety

- Industry requirements and specifications in aerospace and defence

- Differential thermal expansion and contraction

- Field failures and maintenance costs

LED & Lighting Industry Solutions

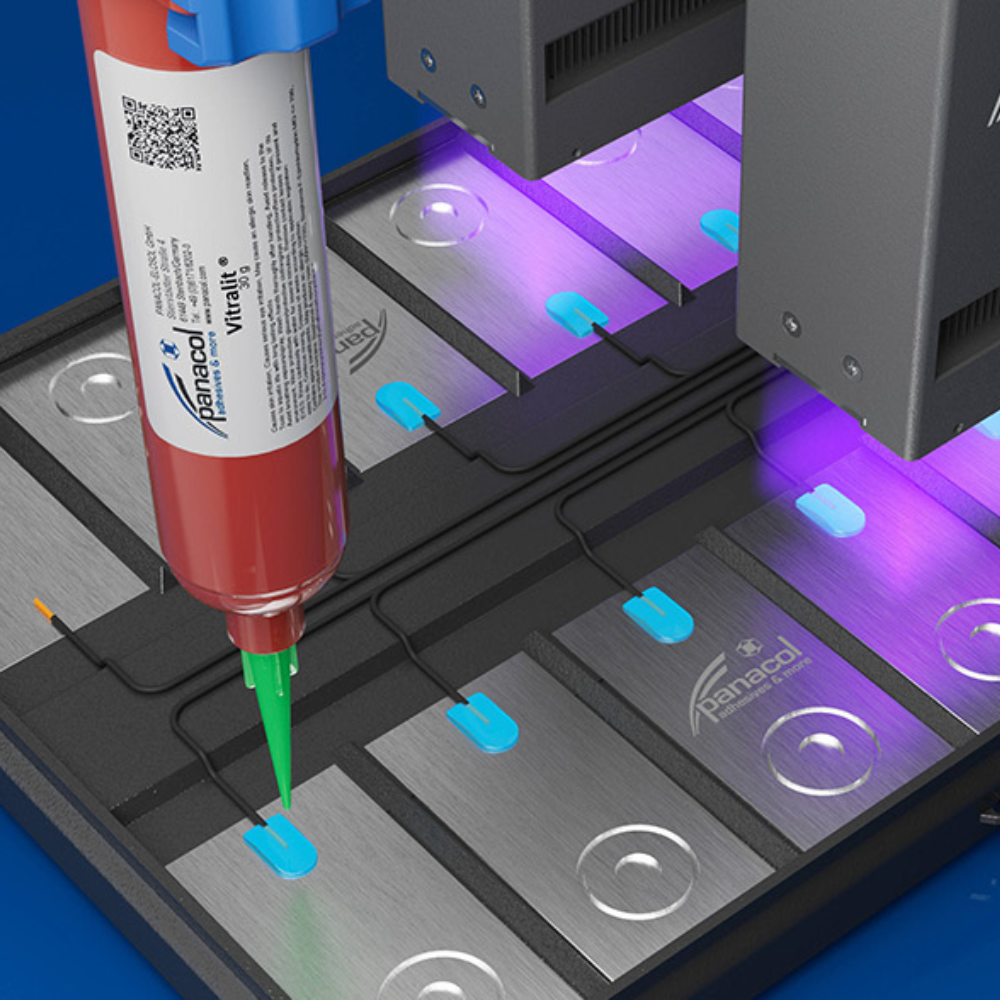

TECHSiL offer a full range of products and materials for lighting and LED applications consisting of heat transfer and thermally conductive silicone systems, tough epoxies, polyurethanes, crystal clear potting materials, encapsulation, contact cleaners and specialist heat transfer tapes. Solutions TECHSiL offer include:

- Liquid Thermal Interface Materials for thin bond lines

- Optically clear and non-yellowing materials

- Plastic enclosure sealants

- LED chip encapsulation and PCB protection

- High strength adhesives for installation

- Wire tacking and cable solutions

- Solutions for bonding dissimilar materials

- Thermally conductive adhesives for heat transfer

- High temperature, dust, and chemical resistant materials

- UL approved, Flame retardant, solvent free, low outgassing, and low VOC options

CONTACT AN EXPERT

DAN WRIGHT

I have been with TECHSiL for over three years, working in a field sales role within the adhesives and sealants sector. With more than 11 years’ experience supporting manufacturers and distributors, I bring a strong understanding of how to identify and deliver effective solutions for complex bonding applications.

I have supported projects across a wide range of industries, including electronics, engineering, motorsport, defence, marine, and aerospace, giving me broad exposure to varied technical and commercial challenges. My key strengths lie in problem-solving and in understanding the critical pain points within a project, enabling me to recommend the most effective and reliable solution. I strongly believe that the best results are achieved through long-term working relationships, and customer satisfaction is central to both my approach and Techsil’s values.

SALES MANAGER | dan.wright@techsil.co.uk | +44 (0)7756 867066 | LinkedIn

INDUSTRY APPLICATIONS

Ensure optimal light transmission for safety and end use with optically clear materials which offer UV stability, are non-yellowing, and do not compromise on light performance. Clear adhesives and sealants allow for inspection and optimised refractive indices where required.

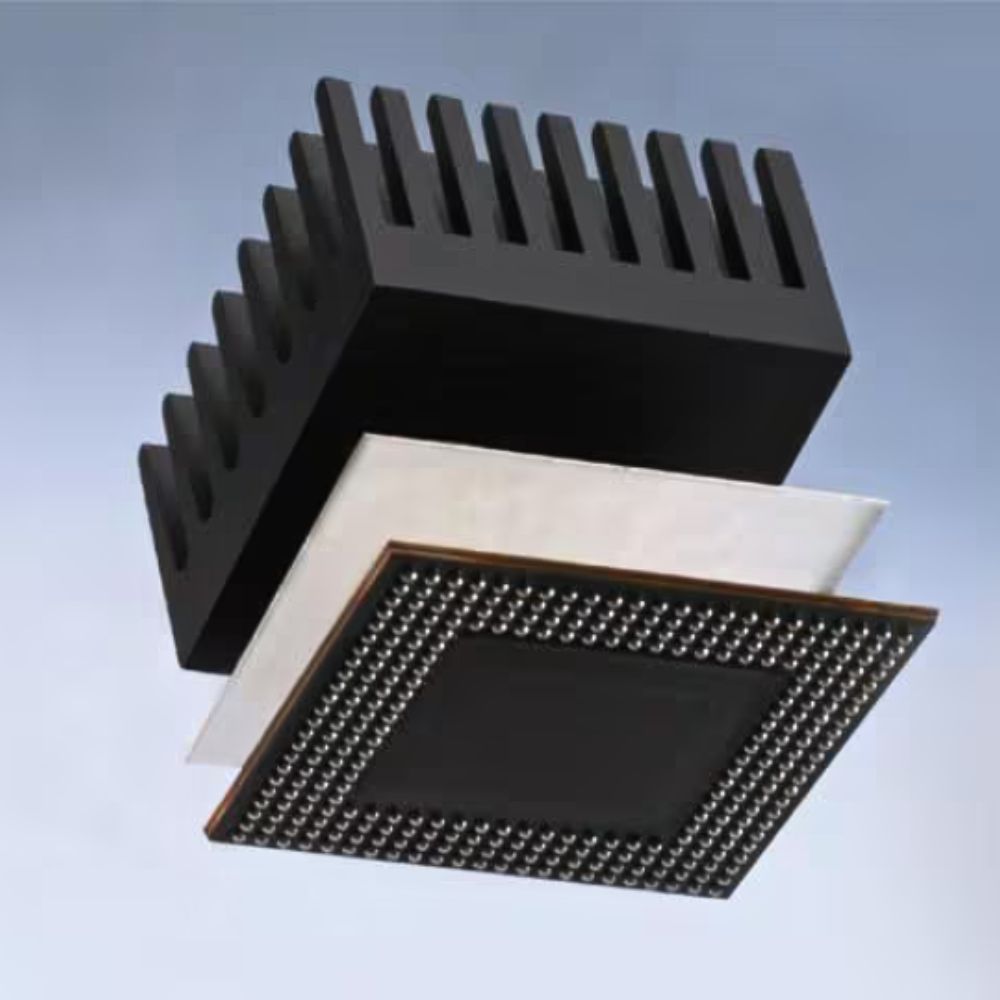

Extend operating life, protect sensitive components, and manage heat generation in diodes by creating heat paths to heat dissipation devices with thermally conductive adhesives, gap fillers, and thermal interface materials.

Transparent potting and encapsulant materials offer PCB protection, chip encapsulation, and glob top domes for chip on board applications. Protect LED components with these durable, non-yellowing materials which effectively transmit light.

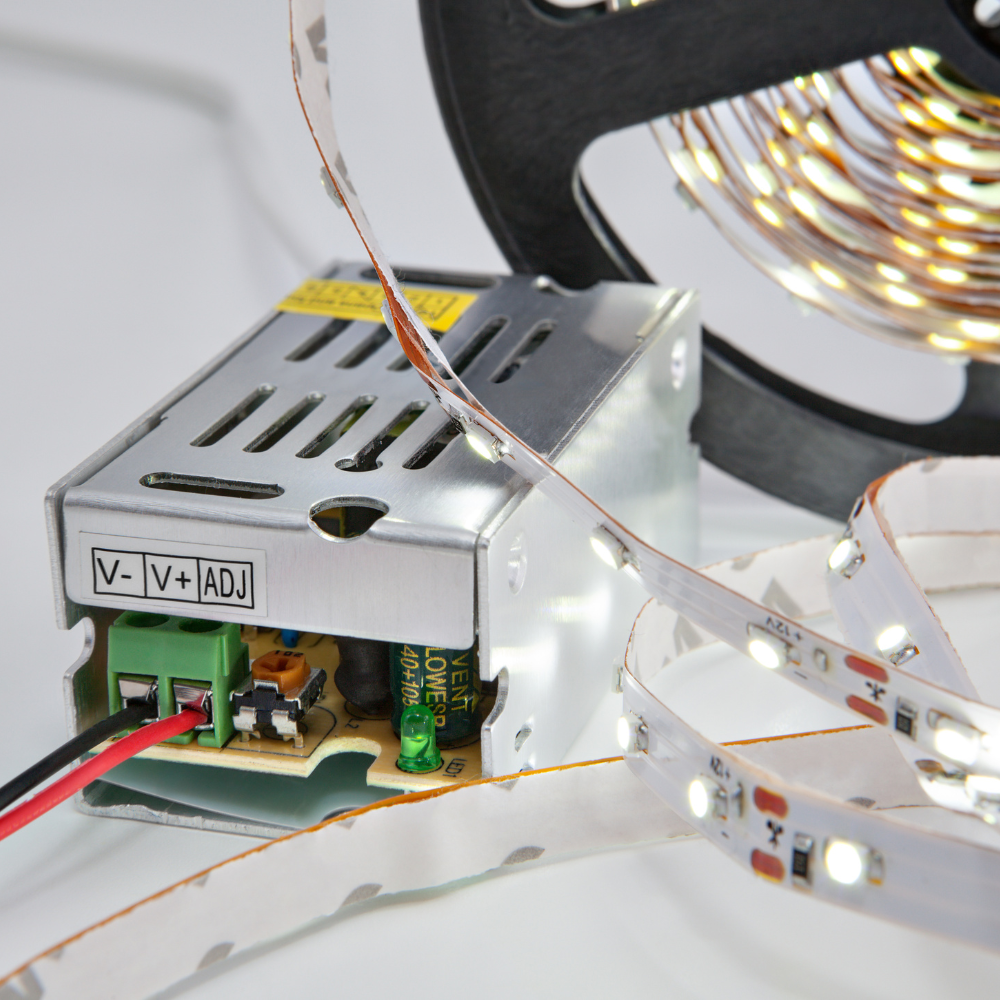

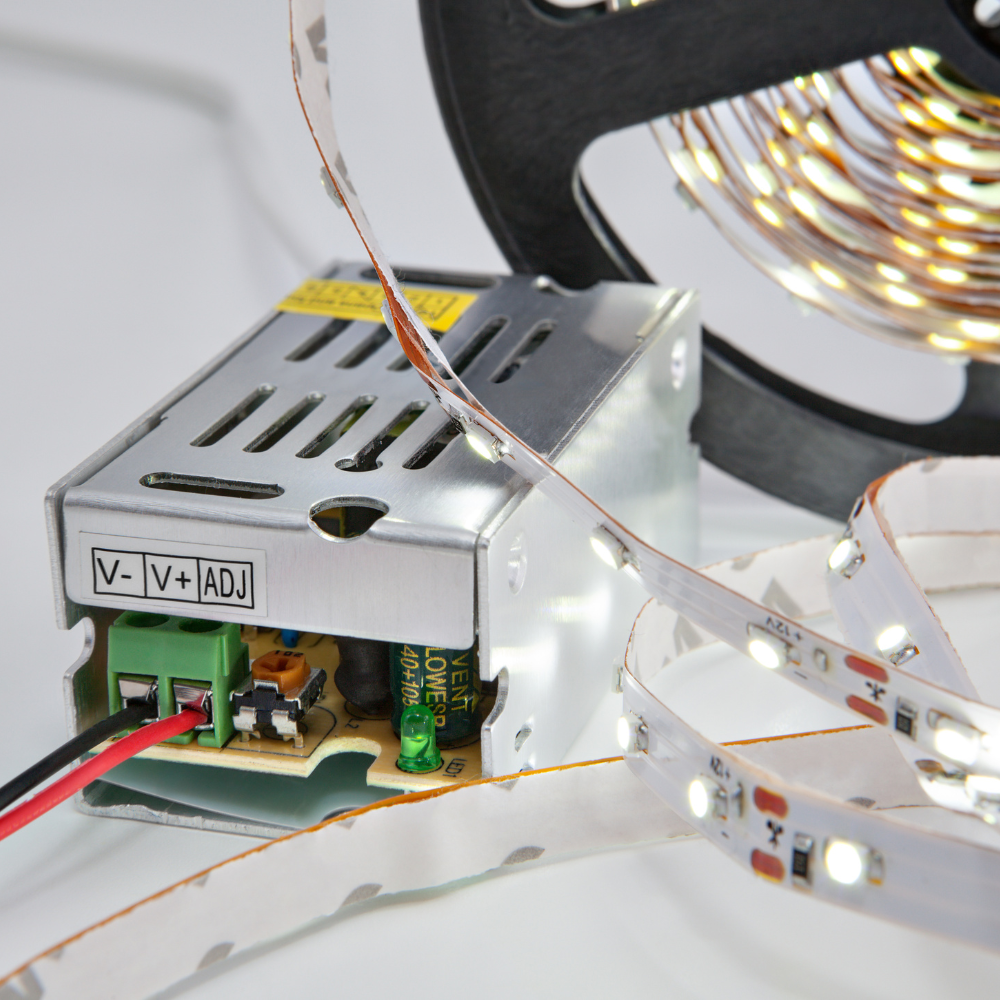

DRIVER & POWER SUPPLY ASSEMBLY

Fill and seal gaps in housings, connectors and power supply units, as well as any gaps in enclosures to prevent moisture, dust, or chemical ingress, and protect sensitive components. Also secure wires and mount LED drivers.

INSTALLATION & FITTING

Streamline installation with adhesives which eliminate the need for traditional fastenings, also improving aesthetics of the finished installation. Secure fittings, prevent field failures and reduce maintenance costs with high strength adhesives and tapes.

SAFETY

Ensure safety standards during production, assembly, and end use with flame retardant materials, low VOC tapes, UL approved materials, solvent free, low VOC, and low outgassing options. As well as thermal management solutions to prevent overheating and dangerous failures.

Protect LED components, sensitive electronics, and cables from environmental factors including weathering, corrosion, UV radiation, vibration and shock in harsh, outdoor, and marine environments.

Secure installation with high strength adhesives and tapes and ensure enclosures are fully sealed to protect against moisture ingress. Bond dissimilar materials and hard to adhere materials, such as thermoplastics with specialised adhesives as well as wire tacking and chip mounting.

Materials for Lighting and LED

Visit our Resource Centre and discover a comprehensive collection of informative videos, white papers, and technical guides that examine our innovative approach to the Lighting & LED industry.

Lighting & LED Products

WHY TECHSiL?

For over 30 years, TECHSiL has supplied high performance materials across industries from our offices in the UK, offering adhesives, silicones, tapes, lubricants, O-rings and related products. With a dedicated team of internal and external sales and customer service professionals, we work together with our customers and suppliers to find the best product solution for your application.

We are not simply a warehousing and distribution operation; we have earned an enviable reputation in customer care and service.

Services We Offer

- Storage and Stock Management

- Techical Expertise

- Onsite Visits and Samples

- Custom Labelling and Repack Facilities

- Kitting and tape slitting

TECHSiL's Assurances and Approvals

- Quality Management Approval: ISO9001:2015

- FDA Approved Products

- RoHS & REACH Compliant Products

- UL Recognised Products

- Full Traceability

PRODUCTS WE SUPPLY

SUPPLIERS WE WORK WITH

LED & LIGHTING INDUSTRY RESOURCES

Visit our Resource Centre and discover a comprehensive collection of informative videos, white papers, articles, and technical guides that examine our innovative approach to the Lighting & LED industry, includng product recommendations and application solutions.

FREQUENTLY ASKED QUESTIONS

The RTV1084G and TIM11123 both have high thermal conductivity values allowing better transfer of heat away from the critical electronic components avoiding the possibility of overheating and damage. These products lend themselves well to protecting and cooling vital high powered LED components because of the high performance.

The 3M TC2810 is suitable for most applications but not if the product requires servicing as the epoxy is a more permanent adhesive solution, also not suitable for heavy thermal cycling.

For maintained transparency, we recommend:

- RTV615

- PU2420LV

- RTV27844

- PU22985

- NP1490

- NP1492

When bonding a metal-core PCB (typically aluminium-backed) to a housing or heatsink, the material must:

- Transfer heat efficiently

- Bond reliably to metal

- Accommodate thermal expansion mismatch

- Maintain electrical insulation

- Survive long-term thermal cycling

Not all “thermal materials” can bond, many are interface-only and require clamping. Common mistakes to avoid would include:

- Using thermal grease and expecting bonding, grease offers no adhesive qualities.

- Over applied bond line, this kills thermal transfer.

- Rigid expoxies in high thermal cycling designs.

- Silicone greases where mechanical strength is needed.

Two sensible suggestions would be:

- Permanent bond: TECHSiL VT2420LV

- Flexible/high-cycle bond: TECHSiL RTV1084G

For optically clear potting, we can recommend: RTV615, PU2420LV, RTV27844, PU22985, NP1490, NP1492

Gap fillers are one of the most effective and under-used ways to improve thermal management in LED luminaires.

Poor heat dissipation can lead to the following issues reduced LED lumen output, Faster colour shift, shortened driver and LED lifetime, and increased warranty failures. Even small air gaps between an LED module and heatsink can dramatically increase thermal resistance. (Air has a thermal conductivity of ~0.025 W/m·K.) Even a “good” metal-to-metal contact still traps air due to surface imperfections.

Air is the enemy of thermal management. Gap fillers eliminate air, stabilise LED temperatures, and extend luminaire lifetime, without redesigning the housing. Use the minimum thickness needed to eliminate air, not to “pack” the space.

Gap Fillers are used to displace air, conform to uneven surfaces, and create a continuous heat transfer path. Where they are used include, LED Module heat sink interface, Driver & Power Supply Components, and LED Strips in Extrusions.

By using gap fillers correctly, you can reduce LED junction temperature by 5–15°C, extend LED lifetime by double, improve colour stability, and reduce driver failure rates.

Corrosion under conformal coating is usually a process or cleanliness issue first, and a materials or coverage issue second.

Why corrosion happens under coatings:

Even a "good" coating can trap or sit on top of:

- Ionic residues (flux activators, salts, handling contamination)

- Moisture (condensation, humidity cycling)

- Voids, pinholes, and poor edge coverage

- Galvanic couples (dissimilar metals & electrolyte)

Once sealed in, those residues and moisture drive corrosion out of sight until failure.

Here are the most effective ways to prevent it, in a practical checklist you can apply to LED drivers, controls, and power electronics.

- Get the PCB truly clean before coating

- Control moisture, not just coating thickness

- Choose the right coating for the environment

- Ensure complete coverage and avoid “shadowing”

- Mask correctly and avoid contamination from masking materials

- Improve adhesion (especially on “difficult” boards)

- Avoid mixing metals and moisture (galvanic corrosion)

- Validate with the right tests

For RTV silicones, harsh environments typically include one or more of the following:

- High or cycling temperatures

- Moisture, condensation, or ingress risk

- Vibration and mechanical shock

- UV exposure and outdoor use

- Electrical stress (high voltage)

- Long service life expectations (10 - 20 years)

For electronics in harsh environments, the best RTV silicones are non-corrosive, high-temperature, flexible materials that protect electronics without introducing stress or corrosion. The Momentive Snapsil range offers some excellent products with characteristics that lend themselves well to harsh environment resistance.

Recommended Products: RTV160, RTV162 and RTV167

- Non-corrosive, electronics grade

- Continuous service up to 260°C

- Excellent dielectric strength

- Long history in aerospace, industrial, and LED drivers

- Typical uses include LED driver assemblies, power supplier, high-temp components, and outdoor luminaires

Avoid the following in harsh environments:

- Acetoxy cure RTVs - These grades will corrode copper

- Rigid epoxies where thermal cycling is severe - the material will not move with the substrates and will be out under massive stress

- Low-temp general purpose silicones outdoors

- Ignoring cure depth in sealed enclosures

DAN WRIGHT

dan.wright@techsil.co.uk

+44 (0)7756 867066

CONTACT THE EXPERTS

Do you have an enquiry?

Reach out to our Technical Team for expert assistance regarding your LED and Lighting application or problem, and book a complimentary consultation.

technical@techsil.co.uk | +44 (0) 1789 774 244