A Technical Guide to Bonded & Self-Centring Seals

Bonded Seals

Originally designed to replace copper washers in higher pressure systems, bonded seals are simple in construction but very reliable. Made up from an elastomeric ring bonded to a metal form (either circular, square or rectangle in shape); the metal disc resists the bursting forces and so limits any distortion of the elastomeric element.

Benefits of Bonded Seals

- Reliable for high and low pressure sealing

- Offers wide temperature resistance

- Metal ring prevents over-compression and extrusion

- Available in a wide range of different elastomers and metals, with all European thread sizes obtainable.

Self-Centring Bonded Seals

Self-centring seals were developed to eliminate leaks due to the seal becoming offset; very similar to the bonded seal but with the additional benefit of pre-assembly on to the threads, reducing production line costs. The thin seal membrane offers little resistance during assembly.

Benefits of Self-Centring Bonded Seals

- Concentrically located

- Positively retained

- Aids the ease of assembly, offers the ability to pre-assemble

- Optimises component stocking

- Simplifies location machining

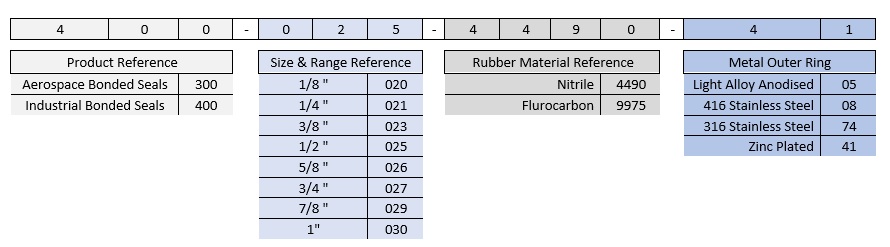

Understanding Bonded Seal Part Numbers

For more detailed information on available references please contact technical@techsil.co.uk.

If you would like to talk to us about your industrial application or production process, please call or message our technical experts:

If you would like to talk to us about your industrial application or production process, please call or message our technical experts: