Trelleborg Sealing Solutions and TECHSiL work closely together as part of a long standing supply relationship supporting UK manufacturers with engineered sealing products. TECHSiL supplies a broad range of Trelleborg sealing technologies, with a particular focus on custom O Rings and associated static sealing solutions for demanding industrial environments Our specialist team is on hand to help find the right solution for a wide varity of applications from Aerospace to Defence and many industrial applications.

Through technical support, stockholding, repacking and application focused guidance, TECHSiL enables customers to access Trelleborg products in a way that aligns with real production requirements, not just catalogue selection.

Protecting the Essential

WHO ARE TRELLEBORG?

Trelleborg Sealing Solutions is a global manufacturer of engineered polymer sealing systems, specialising in elastomer, thermoplastic and PTFE based technologies. Their product portfolio supports a wide range of industrial sectors including aerospace, defence, automotive, energy, semiconductor manufacturing, chemical processing, medical technology and general engineering.

With decades of experience in sealing design, materials science and manufacturing, Trelleborg develops both standard and application specific sealing products. O Rings remain a core part of their offering, supported by advanced material formulations and specialised manufacturing processes for custom sizes and extreme operating conditions.

Trelleborg Sealing Solutions forms part of the wider Trelleborg Group, a company focused on engineered polymer solutions designed to seal, damp and protect critical applications where performance, reliability and consistency matter.

WHY USE TRELLEBORG O-RINGS?

O Rings are one of the most widely used sealing elements in industry, valued for their simplicity, compact design and ability to seal both static and dynamic interfaces. Trelleborg O Rings are manufactured across a wide range of elastomer and high performance polymer materials, allowing compatibility with a broad spectrum of fluids, gases, pressures and temperatures.

Material options include NBR, EPDM, FKM, HNBR, silicone, polyurethane, PTFE and perfluoroelastomer compounds such as Isolast FFKM. This range supports applications requiring chemical resistance, thermal stability, low outgassing, abrasion resistance, electrical insulation or long term sealing stability.

Trelleborg O Rings are available in standard metric and inch sizes to ISO and AS specifications, as well as fully custom dimensions where standard sizes are unsuitable. For large diameter or non standard O Rings, specialised manufacturing methods are used to ensure consistent cross section and mechanical integrity around the full circumference.

PREFERED TRELLEBORG DISTRIBUTOR

TECHSiL is a preferred technical distributor for Trelleborg Sealing Solutions, providing expert access to their world-leading portfolio of engineered polymer components. We combine Trelleborg's elite material science with our specialised application support to deliver high-performance seals tailored to your specific industrial challenges. From technical specification to supply chain management, we ensure you receive proven, traceable products that meet the precise requirements of your mission-critical operations.

AUTHORISED SUPPLY AND VALUE ADD SERVICES?

TECHSiL supplies Trelleborg O Rings as part of a broader sealing and materials portfolio. In addition to product supply, TECHSiL provides value add services that support efficient integration into customer processes.

These services include repacking into application specific quantities, custom labelling, kit assembly, controlled storage and stock management support. O Rings can be supplied in formats suited to production lines, maintenance operations or clean handling environments, reducing waste and handling time.

TECHSiL also supports customers with material selection guidance, drawing reviews and application discussions, helping ensure that sealing performance aligns with real operating conditions rather than assumptions made at specification stage.

Innovative solutions, designed to protect people, infrastructure, industrial equipment and the environment.

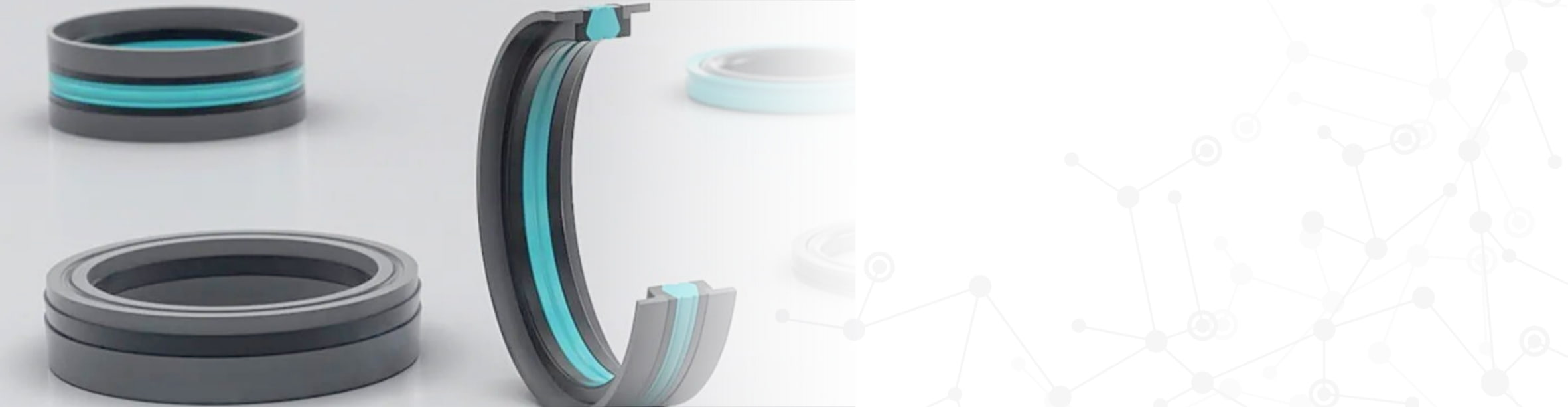

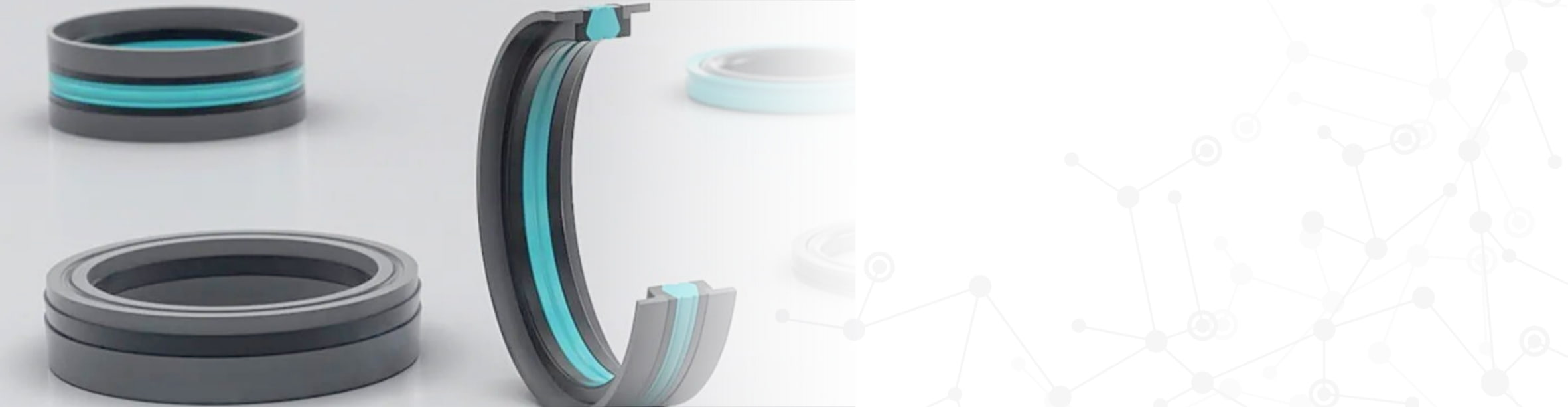

TRELLEBORG O-RING SOLUTIONS

Today, the O-Ring is the most widely used seal because of its inexpensive production methods and its ease of use. We offer you a range of elastomeric materials for both standard and special applications which allow the O-Ring to seal practically all liquid and gaseous media.

The perfect O-Ring for each purpose

Trelleborg O-Rings are both cost-effective and perform highly in almost every environment. No matter if you need metric or inch, standard or custom-made O-Rings – any size of O-Ring seals is available – including giant O-Rings using the Fleximold™ process. The Trelleborg rubber O-Rings are made of EPDM, FKM, NBR, HNBR, as well as our proprietary FFKM, Isolast®. Special products apart from rubber O-Rings such as O-Rings in PTFE based Turcon® material and Wills Rings® metal O-Rings are also available.

Elastomer O Rings

Standard and custom O Rings manufactured from a wide range of elastomer compounds, supplied to ISO and AS sizes or to customer specific dimensions. Suitable for static and dynamic sealing in hydraulic, pneumatic and general industrial applications.

Encapsulated O Rings

FEP encapsulated O Rings combining an elastomer core with a fluoropolymer jacket, offering broad chemical resistance and reduced friction. Often used where media compatibility is critical and standard elastomers are unsuitable.

High Performance O Rings

Perfluoroelastomer O Rings such as Isolast FFKM, designed for extreme temperature and chemical exposure. Commonly used in semiconductor, chemical processing and high specification energy applications where conventional elastomers may not perform reliably.

PTFE O Rings

Machined or formed PTFE O Rings for static sealing applications requiring exceptional chemical resistance and thermal stability. Typically used in flange and face seal configurations.

GET EXPERT ADVICE

Find out more about the Industry Applications of Trelleborg' solutions, or let us help you find the ideal product for your needs no matter what the application.

EXPERT ADVICE

BOOK A COMPLIMENTARY CONSULTATION with one of our experts to help find the perfect products for your needs.

technical@techsil.co.uk | +44 (0) 1789 774 244

WHAT INDUSTRIES USE TRELLEBORG PRODUCTS?

Trelleborg O Rings are widely used across aerospace and defence platforms where reliability over wide temperature ranges and exposure to fuels, hydraulic fluids and aggressive environments is required. Material options include FKM, low outgassing elastomers and perfluoroelastomers for critical sealing interfaces.

Trelleborg sealing products are used across aerospace and defence applications where reliability over wide temperature ranges and exposure to aggressive fluids is required.

O Rings are commonly specified for fuel systems, hydraulic circuits, environmental control systems and structural interfaces. Materials such as FKM, low temperature elastomers and perfluoroelastomers are selected where resistance to fuels, hydraulic fluids, pressure cycling and thermal variation is critical.

Aerospace Trelleborg seals are an integral part of the aerospace industry, found in engines, landing gear, flight controls, and interiors. They provide critical sealing in extreme temperatures and against aggressive jet fuels. Trelleborg Aerospace Solutions Offer:

-

High-temperature stability for engine zones

-

Cryogenic flexibility for high-altitude flight

-

Resistance to Skydrol and jet fuels

-

AS9100 and MIL-spec compliance

-

Proven performance in hydraulic actuators

In automotive and transportation systems, O Rings are used extensively in powertrain assemblies, braking systems, thermal management circuits and fluid handling components.

Trelleborg O Rings are selected for resistance to oils, fuels, coolants and long term ageing under continuous service. Both standard size and custom O Rings are used in production and aftermarket environments, where consistency of sealing performance and dimensional control are required.

Trelleborg develops advanced sealing solutions for the automotive sector, from traditional combustion engines to the latest electric vehicle (EV) battery cooling systems and e-axles. Trelleborg Automotive Materials Offer:

-

Low friction coatings for dynamic seals

-

High thermal conductivity for battery cooling

-

Resistance to new automatic transmission fluids

-

Long-term reliability in rotary shafts

-

Custom geometries for shock absorbers

Energy and oil and gas applications place high demands on sealing systems due to elevated pressures, temperature extremes and aggressive media. Trelleborg O Rings are used in upstream, midstream and processing equipment, including valves, pumps, connectors and instrumentation.

Materials such as HNBR, FKM and FFKM are specified where resistance to hydrocarbons, sour gas, chemicals and pressure cycling is required.

Back up rings and specialist static seals are often used alongside O Rings to support high pressure conditions.

Trelleborg provides robust sealing solutions for the harshest environments on earth, including deep-sea drilling and high-pressure hydrogen storage.

Trelleborg Energy Materials Offer:

-

Rapid Gas Decompression (RGD) resistance

-

Sour gas (H2S) and chemical resistance

-

Extreme pressure capability for downhole tools

-

Hydrogen tightness for renewable energy systems

-

NORSOK M-710 certified materials

In chemical processing and industrial manufacturing environments, sealing materials must withstand exposure to corrosive chemicals, solvents and elevated temperatures.

Trelleborg offers elastomer, encapsulated and PTFE based O Rings suited to static sealing in flanges, vessels, pipework and processing equipment.

Encapsulated FEP O Rings and PTFE seals are often used where chemical compatibility is the primary concern and elastomer exposure must be minimised.

Semiconductor and electronics manufacturing processes require sealing solutions with controlled cleanliness, chemical resistance and, in some cases, low outgassing performance.

Trelleborg O Rings made from perfluoroelastomer and PTFE based materials are used in vacuum systems, process chambers and fluid delivery systems.

Material selection is driven by exposure to aggressive gases, plasma environments and temperature cycling, as well as the need to maintain sealing integrity over long service intervals.

In medical and life science equipment, O Rings are used in devices and systems where material consistency, cleanliness and repeatable sealing performance are required.

Trelleborg sealing products are applied in equipment such as pumps, diagnostic devices and fluid handling systems. Elastomer materials are selected based on compatibility with cleaning agents, sterilisation processes and operating media, as well as dimensional stability.

In the medical sector, Trelleborg components are found in life-saving devices, surgical tools, and biopharmaceutical processing equipment. Trelleborg Medical Solutions Offer:

-

Biocompatibility (USP Class VI, ISO 10993)

-

Resistance to sterilisation (Autoclave, Gamma, EtO)

-

High-purity materials for drug delivery

-

Precision micromoulding for minimally invasive tools

-

Full batch traceability and cleanroom manufacturing

Food, beverage and pharmaceutical processing equipment relies on seals that can withstand cleaning regimes, temperature variation and contact with process media.

Trelleborg O Rings are used in processing machinery, filling equipment and transfer systems where material compliance, cleanability and durability are important. Encapsulated and PTFE based seals are often selected where chemical resistance and hygiene considerations influence material choice.

Across general engineering and heavy industrial applications, O Rings are used in machinery, hydraulic systems, compressors and fluid control equipment.

Trelleborg provides standard and custom O Rings to suit a wide range of pressures, temperatures and operating conditions.

Material selection is typically driven by mechanical demands, media compatibility and service life expectations rather than regulatory constraints.

TRELLEBORG SEALING SOLUTIONS

Isolast® Perfluoroelastomer (FFKM)

Providing the ultimate in thermal and chemical resistance, Isolast materials allow for continuous operation in temperatures exceeding 320°C. These high-specification O-rings are preferred for aggressive chemical processing and semiconductor fabrication where standard elastomers fail.

Key Characteristics

- Extreme Temperature Resistance: Operates from very low temperatures to over 325°C (617°F).

- Broad Chemical Resistance: Withstands nearly all chemicals, including strong acids, amines, solvents, and steam (for SIP/CIP).

- High Purity Grades: Available in specialized versions (like PureFab®) for ultra-clean semiconductor and biotech environments.

- Excellent Mechanical Properties: Offers good resilience, compression set, and durability for long-lasting seals.

- Versatile Formats: Available as O-rings, custom molded parts, and bonded parts (rubber-to-metal/plastic).

Common Applications

- Semiconductor Manufacturing: Plasma sealing, wafer processing.

- Pharmaceutical & Biotech: Bioreactors, mass spectrometers, sterile processing (SIP/CIP).

- Chemical Processing: Pumps, valves, and reactors handling aggressive media.

- Oil & Gas: Downhole tools, extreme-temperature applications.

FFKM vs. FKM (Viton®)

- FFKM (Isolast®): Fully fluorinated, offering superior chemical and thermal performance, almost like PTFE but with elasticity.

- FKM (Viton®): Partially fluorinated, offering good performance but not at the extreme levels of FFKM, making it a more cost-effective choice for less demanding applications.

Turcon® Engineered PTFE

Characterised by exceptionally low friction and excellent self-lubricating properties, the Turcon range is ideal for dynamic sealing. These materials virtually eliminate stick-slip and offer superior wear resistance, making them excellent candidates for high-speed robotics and fluid power systems.

- Material Base: Virgin PTFE fluoropolymer resin.

- Enhanced Properties: Fillers (like glass, carbon, graphite) and proprietary processing improve properties like wear resistance, thermal conductivity, and electrical conductivity (Turcon® MC1/MC2).

- Chemical Inertness: Compatible with nearly all chemicals and lubricants, resisting aggressive media.

- Low Friction & Wear: Self-lubricating, offering excellent friction and wear characteristics for dynamic seals.

- Wide Operating Range: Performs well across extreme temperatures, pressures, and velocities.

- Hardware Protection: Reduces abrasion on mating metal surfaces, extending hardware life.

- Hydraulics: For pumps, cylinders, and valves needing high performance and durability.

- Semiconductors: In vacuum pumps, valves, and robotics due to chemical purity and low outgassing.

- Rotary & Reciprocating Seals: Used in various seal types like Variseals® (spring-energized) and Roto Glyd Rings®.

Zurcon® High-Performance Polyurethane

Engineered for heavy-duty environments, the Zurcon range offers extraordinary abrasion resistance and mechanical strength. These seals are specifically designed to withstand high pressure and rugged conditions, making them the industry standard for hydraulic cylinders and industrial actuators.

- Outstanding Resistance: They provide excellent resistance to wear, extrusion (operating at pressures up to 40 MPa/ 5,800 psi without a back-up ring), and abrasion.

- Wide Temperature Range: Specific grades, such as Zurcon® Z25, can operate in temperatures from -35°C up to +130°C (-31°F to +270°F).

- Low Compression Set: The materials are formulated to have very low compression set values, ensuring reliable sealing over a long service life.

- Fluid Compatibility: Zurcon® materials are compatible with a variety of fluids, including mineral oil-based hydraulic fluids, synthetic ester fluids, and water-based fluids.

- Superior Dynamic Performance: They maintain resilience and provide excellent friction properties, even in cylinders with lower quality inner walls.

- Hydrolysis Resistance: Certain grades like Zurcon® Z13 and Z24 offer good resistance to hydrolysis, making them suitable for water-based applications.

- UV Resistance: Zurcon® Z82 is a specialized grade developed for applications exposed to direct sunlight, such as in offshore oil & gas or mobile equipment, due to its superior UV resistance.

- Heavy-Duty Cylinder Sealing: Ideal for use in industrial and mobile applications, such as construction machinery, earthmoving equipment, mobile cranes, and forklift trucks.

- High-Pressure Environments: Used in systems with limited cooling or those exposed to high-temperature processes, such as painting, due to their improved heat resistance.

- Rotary Applications: Suitable for uses like swivel joints where high pressures and low speeds generate heat.

- Aerospace & Defense: Utilized in various aerospace components including flight controls, landing gear seals, and fuel systems, where reliability in extreme environments is paramount.

- Oil & Gas: Used in both offshore and onshore facilities for seals that need to endure harsh environmental conditions and intense pressure.

- Food Processing: Employed in pumps and valves for food processing due to their durability and chemical resistance properties.

XploR® RGD Resistant Seals

Developed specifically for the energy sector, XploR materials are formulated to resist the destructive effects of Rapid Gas Decompression. These O-rings maintain structural integrity under extreme pressure cycles and are proven to survive exposure to sour gas and harsh wellbore chemicals.

- Extreme Pressure Resistance: Seals can withstand pressures up to 103.4 MPa (15,000 psi) in static applications.

- Broad Temperature Range: Operating limits vary by material grade, typically ranging from -45°C to +260°C (-49°F to +500°F).

- Industry Compliance: Materials are independently tested and certified to international standards, including NORSOK M-710, ISO 23936-2, NACE, and API.

- Sour Gas Resistance: Engineered to remain stable in high-concentration H2S (sour gas) environments.

- Isolast® (FFKM): Offers the ultimate chemical and thermal resistance. Grade J9513 was the first perfluoroelastomer to meet NORSOK M-710 RGD requirements.

- XploR™ V9T82 (FKM): Provides industry-leading low-temperature RGD performance down to -48°C (-54°F).

- XploR™ HNBR & Aflas®: Formulated for balanced performance in moderately aggressive media where FFKM may not be required.

- Standard O-Rings: Available in all international standard sizes.

- S-Seal & FS-Seal: Features integral, corrosion-resistant metallic springs molded into the elastomer for maximum extrusion resistance and easier installation.

- Custom Profiles: Engineered for specific downhole tools, wellheads, and valve applications.

- Upstream Oil & Gas: Wellheads, tubing hangers, casing strings, and Christmas trees.

- Downhole Tools: Drilling motors, logging tools, wireline tools, and packers.

- Subsea & Process: Blowout preventers (BOPs), swivel stacks on FPSO vessels, and flowline equipment.

FoodPro® Hygienic Materials

Designed to meet the stringent safety requirements of the food, beverage, and pharmaceutical industries. These materials are fully compliant with FDA and EC 1935/2004 regulations, offering excellent resistance to aggressive Clean-In-Place (CIP) media while ensuring zero flavour carryover.

- Global Regulatory Compliance: Fully compliant with major 2026 standards, including FDA 21 CFR 177, EU Reg. (EC) 1935/2004, Chinese GB standards, and the Japanese Positive List.

- Superior Process Resistance: Specifically engineered to withstand Cleaning-in-Place (CIP) and Sterilisation-in-Place (SIP) regimes, including exposure to steam up to +150°C (+302°F) and harsh alkaline or acidic cleaning agents.

- Hygienic Surface Technology: Formulated using "ultra-clean" technology to produce high-gloss, low-porosity surfaces that prevent bacteria buildup and reduce particle shedding.

- Versatile Material Grades:

- EPDM (e.g. E75F2): Universal "all-rounder" with high chemical resistance in polar solvents and steam.

- High-Pressure Grades (e.g. E85F2): Increased hardness (80 Shore) for enhanced extrusion resistance in high-pressure systems.

- Specialty Grades (e.g., E75F1): Developed with low carbon black levels for sensitive applications like infant formula processing.

- Mechanical Integrity: High tensile strength, tear resistance, and wear resistance even under dynamic conditions.

- Dairy & Beverage Processing: Ideal for separators, decanters, and homogenizers where steam and hot water resistance are critical.

- Filling & Dispensing Systems: Used in high-pressure filling machines and aseptic flange connections.

- Fluid Handling Components: Essential for pumps, valves (including mix-proof valves), and pipe couplings.

- Heat Transfer Equipment: Durable gaskets for plate heat exchangers and tanks.

- Specialised Machinery:

- Coffee Machines: Using Turcon® FoodPro® for its high abrasion resistance and low friction.

- Dosage Cylinders: Utilising Zurcon® FoodPro® for reciprocating applications requiring extreme wear resistance.

- Hygienic Connections: Specialised flange gaskets (e.g. HMF48) for secure, leak-proof piping systems.

FlexiMold™ Custom O-Rings

Enabling the cost-effective production of large-diameter and non-standard O-rings without the requirement for dedicated tool inserts. This proprietary process ensures the same high-quality integrity as a moulded part, providing a flexible solution for bespoke machinery and prototype development.

- No Tooling Charges: For O-rings with standard cross-sections, the flexible tooling setup eliminates the significant cost and lead time associated with manufacturing dedicated molds for large diameters.

- Full Dimensional Integrity: Unlike seals made by splicing extruded cords, FlexiMold™ O-rings are continuously molded with no joints, ensuring uniform strength, visual integrity, and consistent performance.

- Infinite Diameter Capability: The technology is recommended for O-rings over 500 mm (20 inches) in diameter and can produce seals of almost infinite diameter, including very large sizes used in applications like FPSO swivels (up to 20 feet in diameter).

- High-Quality Tolerances: Seals are produced to tight tolerances and meet international standards like ISO 3601-1, AS568, and JIS B 2401.

- Wide Material Availability: Available in a variety of high-performance elastomers, including proprietary Isolast® FFKM (perfluoroelastomer), FKM, EPDM, HNBR, and Resifluor™ high-performance fluoroelastomers.

- Surface Finish Options: The Flexfinish™ option can provide an exceptionally even surface finish with minimal flash height, ideal for high-vacuum or toxic gas applications to eliminate potential leak paths.

- Oil & Gas: Used in large-diameter equipment such as FPSO (Floating Production Storage and Offloading) swivels, natural gas filter doors, and wellhead equipment.

- Pharmaceutical & Food & Beverage: Utilized in large vessels, filters, and other processing equipment where FDA or USP Class VI compliant materials are required for hygiene and chemical compatibility with cleaning media.

- Semiconductor & Electronics: Essential for large cover seals in the production of flat panel displays and other high-vacuum processes where high purity and zero defects are crucial.

- Power Generation: Used in general power generation equipment where durable, large-scale seals are necessary.

- Marine & Wind Energy: Employed in wind turbines and other large infrastructure where seals must endure harsh environmental conditions.

O-RINGS

SUITABLE MATERIALS:

Trelleborg O Rings are available in elastomer and polymer materials selected to suit oils, fuels, hydraulic fluids, solvents, gases and aggressive chemical media. Material selection is based on operating temperature, pressure, motion, fluid compatibility and service life expectations.

WHAT ARE TRELLEBORG O-RINGS?

O Rings are circular sealing elements with a round cross section, designed to be installed into a groove and compressed between mating surfaces to prevent the passage of fluids or gases. They are used in static, reciprocating and rotary applications across a wide range of industries.

TYPICAL APPLICATIONS:

Some of the typical applications for Trelleborg O-ring products supplied by TECHSiL include:

- Hydraulic and pneumatic systems

- Flange and face seals

- Valve and pump assemblies

- Vacuum systems

- Chemical processing equipment

- Semiconductor manufacturing tools

WHY USE TRELLEBORG O-RINGS?

Some of the key benefits of using Trelleborg O-rings include:

-

Elite Material Portfolio: Access to high-specification brands such as Isolast (FFKM) and Turcon (PTFE).

-

Extreme Temperature Resistance: Reliable performance in environments ranging from -200°C to over +320°C.

-

Proven Chemical Compatibility: Materials tested against thousands of aggressive industrial fluids and gases.

-

Rapid Gas Decompression (RGD) Resistance: Specialized compounds that prevent seal rupture in high-pressure cycles.

-

Full Batch Traceability: Comprehensive documentation and certification for mission-critical sectors.

-

Low Friction and Wear: Self-lubricating properties that extend the service life of dynamic equipment.

-

Custom Geometric Solutions: Capability to provide non-standard sizes through the FlexiMold manufacturing process.

FAQs

Choose a lubricant whose base chemistry is compatible with EPDM, then confirm against the specific EPDM compound used in the Trelleborg O ring. EPDM is generally suitable for water based media and brake fluids, but it is not compatible with many mineral oil based lubricants. Where there is any doubt, a short immersion check measuring volume and hardness change at operating temperature is the practical way to confirm suitability. TECHSiL can support lubricant selection alongside Trelleborg EPDM O rings so the seal and lubricant behave as a system.

Selection starts with compatibility between the lubricant and the Trelleborg O ring material, followed by suitability for the device media and operating conditions. Cleaning and sterilisation cycles must also be considered. Validation typically includes friction, wear and ageing checks under representative conditions. TECHSiL supports medical device projects by helping define the correct O ring and lubricant pairing early in development.

Low compression set performance depends on the specific silicone formulation rather than silicone in general. Selection should be based on operating temperature, compression level, gasket geometry and expected service life. Cure quality is also critical, as incomplete or inhibited cure can lead to permanent deformation. TECHSiL supports silicone gasketing selection and process set up to help maintain long term sealing performance.

Sensor safe gasketing usually relates to selecting a silicone with an appropriate cure system and controlled outgassing behaviour, combined with good contamination control during assembly. The exact requirements depend on what the sensor is sensitive to, such as corrosion, fogging or byproducts in enclosed spaces. TECHSiL can help define suitable materials and validation steps for sensor adjacent sealing applications.

Cure time is best reduced by matching the silicone material to bead size and cure environment, then controlling surface preparation, dispense parameters and cure conditions together. Temperature, humidity and contamination all influence cure behaviour. TECHSiL supports form in place gasket processes and can help optimise cure without sacrificing seal integrity.

Trelleborg Sealing Solutions supplies O rings, static seals, hydraulic seals, rotary seals, gaskets, oil seals and pneumatic sealing products in the UK. The O ring range includes elastomer O rings, PTFE O rings, encapsulated O rings, polyurethane O rings and large diameter O rings manufactured using Fleximold technology. TECHSiL supplies these products with technical and logistical support.

Common O ring types include elastomer O rings for general static and dynamic sealing, PTFE O rings typically used in static face or flange sealing, encapsulated O rings used where chemical resistance drives selection, polyurethane O rings used in more demanding dynamic duties, and perfluoroelastomer O rings used where temperature and chemical exposure are severe. Related products such as Quad Rings and back up rings are often used alongside O rings to improve stability, sealing efficiency or extrusion resistance in specific designs.

Start with the operating media, temperature range, pressure range and whether the seal is static, reciprocating or rotary. Then confirm the groove design, squeeze and surface finish, because housing details drive performance. Select the Trelleborg O ring material first, then hardness and size standard, and finally consider installation method and lubrication. TECHSiL can help you choose the correct O ring type and size, standard or custom, and sanity check the housing assumptions.

Inspect grooves for burrs, corrosion and sharp edges before fitting, then replace seals once removed rather than reusing compressed rings. Keep housings clean, avoid mixing seal materials in storage, and store elastomers away from heat, UV and ozone. When failures repeat, identify the failure mode, extrusion, swelling, abrasion or compression set, then adjust material or housing accordingly. TECHSiL can help interpret failure modes and advise on corrective changes using Trelleborg guidance.

You can buy high quality blue O rings from TECHSiL, supplied to specification using Trelleborg materials. Colour is typically an identifier and should not be treated as a performance rating on its own. Define the material, hardness, size standard and operating conditions, and TECHSiL can supply the correct blue O ring in standard or custom sizes.

Choose based on engineering conditions, then treat colour as a secondary requirement. Confirm housing clearances, pressure and media, then select material and hardness to control extrusion and wear. In higher pressure housings, a back up ring may be required alongside the O ring. TECHSiL can review your groove dimensions and operating conditions and recommend a suitable Trelleborg O ring and support components.

PTFE O rings are typically used for static face or flange sealing where chemical resistance and high temperature stability are required. Confirm the joint is truly static, then confirm the required compression, flatness and tolerance control, because PTFE does not behave like an elastomer. TECHSiL can help you decide whether a PTFE O ring is the right approach for the housing, or whether a different Trelleborg seal type is more suitable for the same temperature profile.

Automotive engines commonly use RTV silicone liquid gasket sealants for joints and flanges exposed to oils and coolants. Selection depends on the joint design, fluid exposure, temperature profile and production process requirements such as dispense method and cure time. TECHSiL supplies engine sealing materials and can advise on selecting the right sealant type for your specific joint and service conditions.

EPDM rubber gaskets are commonly selected for resistance to weathering, ozone and UV exposure, and for compatibility with many water based media. Suitability depends on the specific EPDM compound and operating conditions. TECHSiL can help select an EPDM gasket or O ring approach using the real media, temperature and service life requirements.

EPDM rubber seals and gaskets are commonly used in water handling, HVAC, building services, appliances and outdoor equipment where weathering resistance is important. They are also used in some automotive and general industrial applications where the operating media suits EPDM compounds. TECHSiL can help confirm whether EPDM is appropriate for your sealing environment and lubricant choices.

Many silicone gasket materials retain flexibility at elevated temperatures and can be formulated for specific chemical exposures, but suitability depends on the silicone chemistry, cure quality and the type of chemical contact. Define continuous temperature, peak temperature and exposure mode, then validate in representative conditions. TECHSiL can advise on silicone gasket selection and sensible validation steps for demanding environments.

TRELLEBORG RESOURCES

Visit our Resource Centre to access technical guides, material information and application focused content relating to Trelleborg sealing solutions. Resources cover O Ring design considerations, material selection and industry specific sealing challenges.

TRELLEBORG VIDEOS

WHY CHOOSE TECHSiL?

We are not simply a warehouse and distribution operation; we have earned an enviable reputation in customer care and service

For over 30 years, TECHSiL has supplied high performance materials across industries from our offices in the UK, offering adhesives, silicones, tapes, lubricants, O-rings and related products. With a dedicated team of internal and external sales and customer service professionals, we work together with our customers and suppliers to find the best product solution for your application.

EXPERT ADVICE

BOOK A COMPLIMENTARY CONSULTATION with one of our experts to help find the perfect products for your needs.

technical@techsil.co.uk | +44 (0) 1789 774 244