HOENLE UV TECHNOLOGY

TECHSiL are proud to partner with Hoenle to supply high performance UV curing systems and UV/LED technology across industries. Contact our Technical Team to find out which Hoenle system works for your application.

"THE ENTIRE SPECTRUM FOR CURING"

WHO ARE HOENLE?

Hoenle are UV specialists, being one of the leading suppliers of industrial UV technologies worldwide. They develop, manufacture, and market UV and LED technologies to meet customer requirements, including adhesive systems, handheld UV equipment, curing chambers, LED-UV equipment, measuring devices, lamps, sensors, and more.

WHAT IS UV TECHNOLOGY?

UV technology is a solution for efficient drying and curing in various applications. By using UV radiation in the wavelength range of approximately 200 to 480 nm, adhesives, varnishes, and coatings can be fully cured within seconds. A typical UV system consists of a lamp, reflectors, lamp housing, cooling system, and electronic control and regulation components.

WHY USE UV TECHNOLOGY?

UV technology offers significant advantages over traditional curing methods including faster processing speeds, room temperature operation, precise dose control, seamless

integration with automated production lines, and cost effectiveness by reducing operating expenses and increasing productivity.

WHAT INDUSTRIES REQUIRE UV TECHNOLOGY?

MEDICAL

The medical industry utilises UV technology for manufacturing critical devices where biocompatibility, sterility, and precision are paramount. UV equipment effectively cures biocompatible adhesives specifically formulated for medical applications. Additionally, UV systems maintain sterile conditions through enclosed curing chambers, creating controlled atmospheres and precise delivery.

Medical UV applications include needle bonding, optical devices, and precision bonding on delicate components.

AUTOMOTIVE

The automotive industry uses UV technology for high-speed, highvolume manufacturing where precision and durability are essential. UV technology can be utilised in headlights to bond lenses to housings, cameras, as well as sealing gaskets without thermal stress. It’s also ideal for production lines to ensure uniform coverage across body parts, trim pieces, and interior components.

UV systems seamless integrate with automotive assembly lines through automated conveyor systems, robotic positioning, and PLC controls that synchronize UV exposure with production timing. Automotive UV applications include headlights, body panelling and paint, liquid gaskets, and repairs.

OPTICAL

The optics and glass industry relies on UV technology for its ability to create strong, optical bonds and is ideal for critical areas where lenses and optical elements must be joined with extreme accuracy.

UV systems effectively handle curved and irregular optical surfaces, and can be conformed to complex geometries, ensuring a uniform cure.

UV technology maintains the dimensional stability and optical clarity essentially in applications ranging from camera lenses and microscope objectives to telecommunication components and laser optics.

ELECTRICAL

The electronics industry utilises UV technology for precision bonding and rapid, low temperature curing, essential for high volume electronics manufacturing UV equipment generates minimal heat, making it ideal for curing conformal coatings and adhesives on heat sensitive electronic components, and the ability to instantly cure helps to protect PCBs from moisture and dust ingress.

Electronic UV applications include PCBs, touch screens, sensors, modules, and fibre optic cables.

HOENLE PRODUCTS

CONVENTIONAL UV TECHNOLOGY

A proven solution for efficient drying and curing. By using UV radiation in the wavelength range, roughly 200 to 480 nm, inks, varnishes, and coatings can be fully cured within seconds. Typically a UV system includes lamp, reflectors, lamp housing, cooling system, electronic control and regulation components. The coordination of these elements allows for seamless integration into existing processes. This range includes the Bluepoint 4 and Bluepoint 4 Ecocure.

LED-UV EQUIPMENT

Applied for final curing inks, varnishes, silicones and for bonding, curing and fixing UV adhesives and casting compounds. Hoenle LED curing equipment offers intensity output control, multi-cycle programmability, and RS232 interface for external programming and operation. Most Hoenle power supplies will drive multiple LED heads that can be programmed for sequential or independent actuation. Range includes the Bluepoint LED and LED Spot.

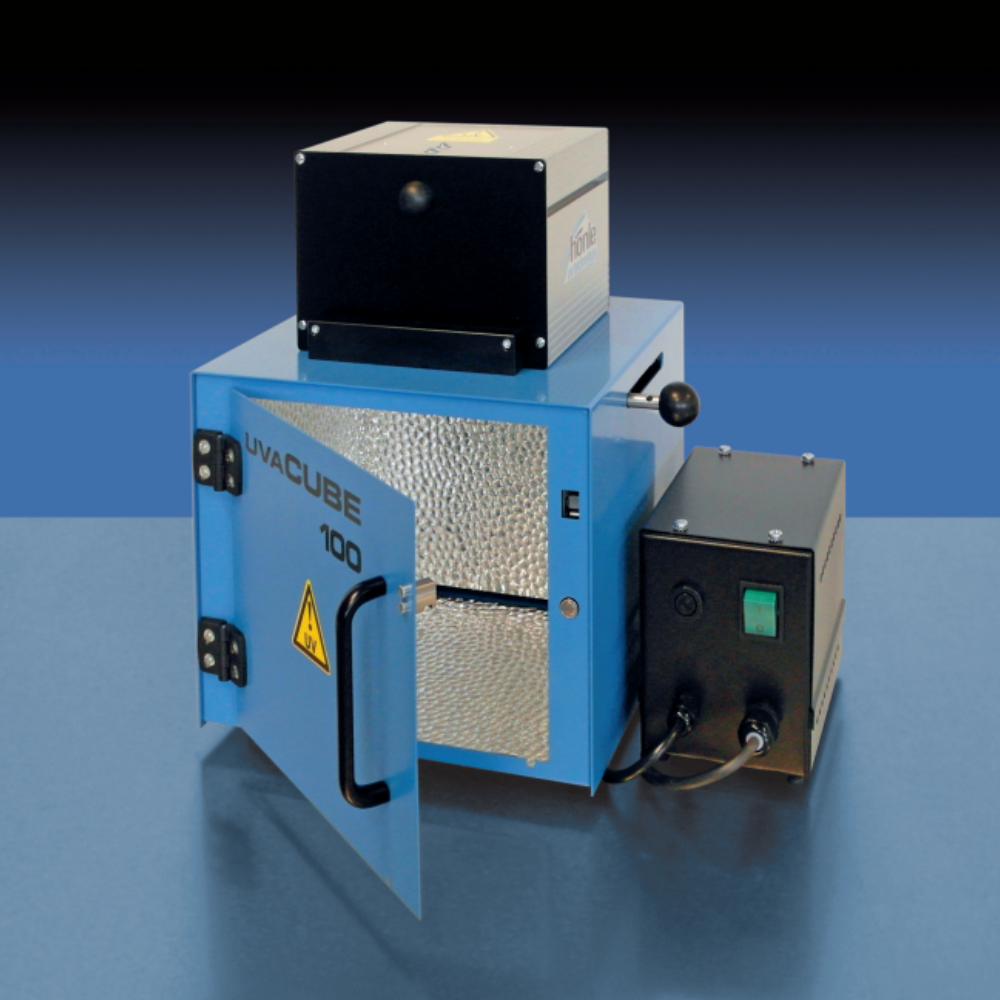

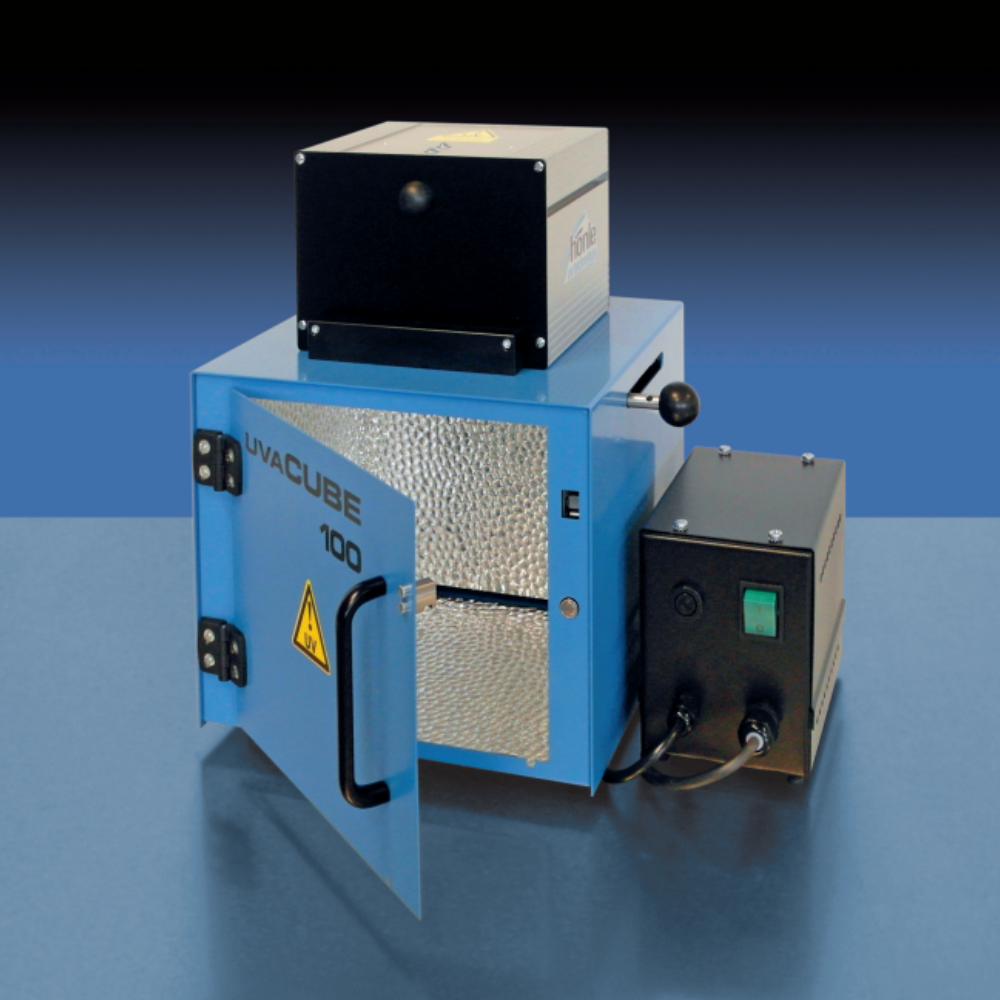

UV CURING CHAMBERS

UV curing chambers are ideal for bonding, curing and drying applications. UV reflective plates ensure homogeneity on the irradiated surface for reliable and repeatable UV emission. Hoenle’s UV curing chambers are suitable for laboratory use or manual production. The safety system of the curing chambers reliably protects personnel from UV radiation. The range includes the LED Cube and UVACube.

HANDHELD CURING EQUIPMENT

Handheld UV curing equipment is designed for assembly applications involving UV curable adhesives, coatings, and sealants. High intensity, portability, and reliability make this UV equipment ideal for R&D laboratories and manual workstations. The UVAHAND provides wide area curing while the LED Pen and LED Power Pen delivers high intensity focused curing.

UV MEASURING UNITS

UV measurement equipment is essential for ensuring reliability and maintaining high standards in quality assurance. By continuously monitoring UV intensity, dose and spectrum, minor variations are detected immediately. The Hoenle UV Meter is a handy uv measurement device suitable for broad spectrum UV and LED light systems. A wide range of sensors accommodate the measurement of various equipment types and wavelengths.

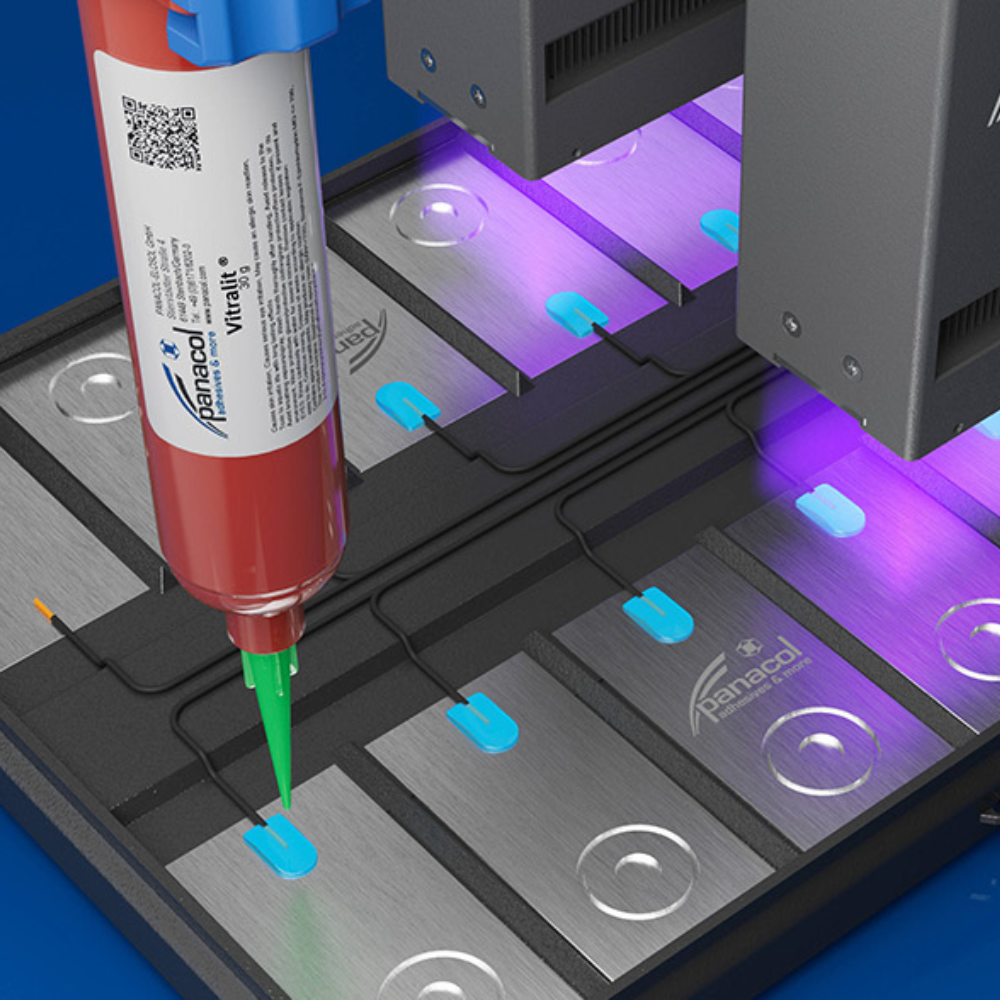

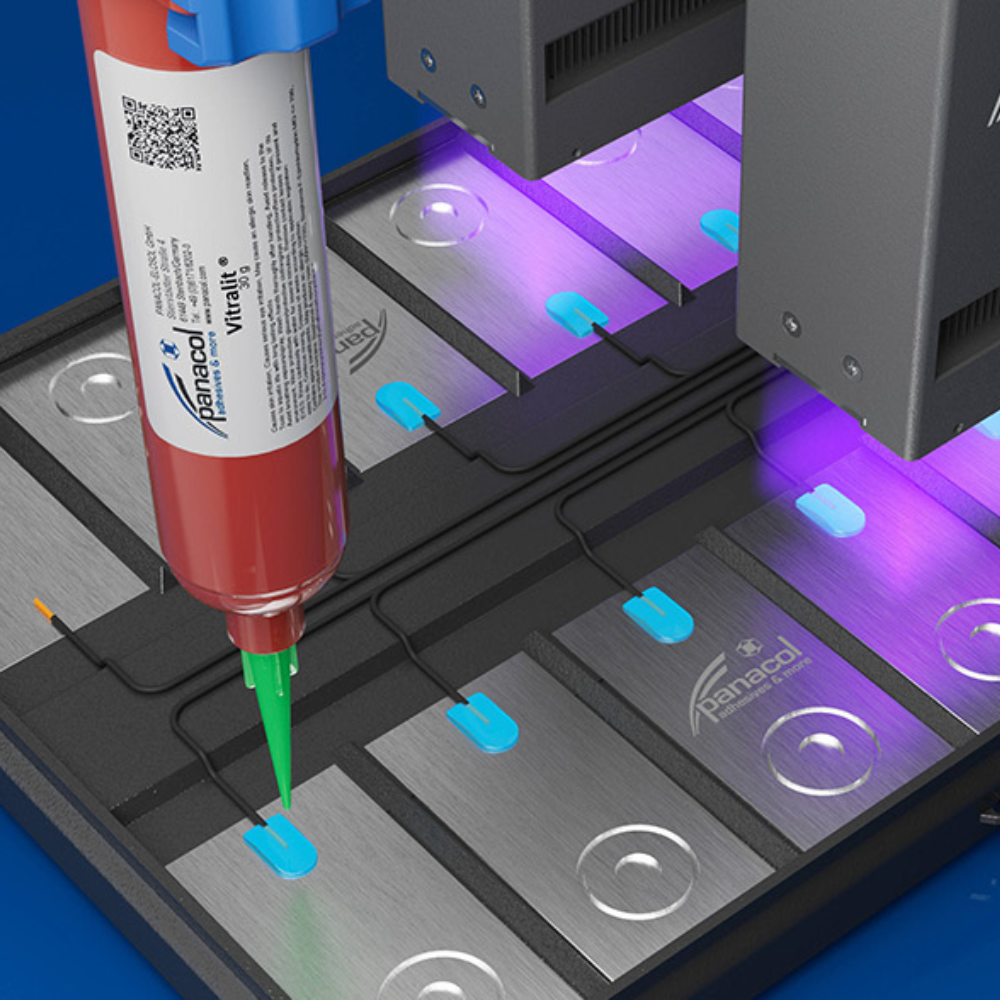

INDUSTRIAL ADHESIVES

Hoenle offer a comprehensive range of special-purpose industrial adhesives for use in industrial applications, ranging from structural adhesives to conductive adhesives and cyanoacrylates. All adhesives and UV equipment can be individually tailored to your requirements to ensure rapid bonding of maximum quality. Their adhesive ranges include: Vitralit, Structalit, Elecolit, and Cyanolit.

HOENLE RESOURCES

Visit our Resource Centre and discover a comprehensive collection of articles, videos, white papers, technical guides and brochures for use across industries and applications.

FREQUENTLY ASKED QUESTIONS

Choosing the right system depends on various factors from production processes to working area. For example, the LED Pen is ideal for hard-to-reach areas, the Bluepoint LED is good for automated manufacturing process, and the LED Cube UV irradiation chamber is good for laboratory or manual production.

Contact our Technical Team for personalised support and guidance regarding the appropriate system for your application.

UV measurement equipment is essential for ensuring process reliability and maintaining high standards in quality assurance and consistent results. Handheld measurement devices allow fast and flexible assessment of UVA, UVB and UVC wavelength ranges, as well as LED-based systems.

LYes, however for maximum efficiency and shortest curing cycle in bonding and potting applications, pair Hoenle UV-LED systems with Hoenle UV/LED curable adhesives, as their wavelengths and materials are specifically designed to complement each other.

Typically, the service life of an LED is 20,000 hours or more, while the UVA lamp typically last 3,000 hours. Replacements are available as well as sensors and cables. Contact our Team for more information.

There are a few factors like depth and distance that need to be considered when choosing the right wavelength lamp.

Reach out to the technical team to discuss your application in more detail

CONTACT AN EXPERT

Do you have an enquiry or question about UV technology, adhesives, or Hoenle products? Reach out to our Technical Team for assistance or fill in a contact form.

Clair Edmunds

INSIDE SALES MANAGER

clair.edmunds@techsil.co.uk

+44 (0)7756 286 802

Slater Jinkinson

SALES DIRECTOR

slater.jinkinson@techsil.co.uk

+44 (0)7765 668959

Do you have an enquiry?

Reach out to our Team for expert assistance.

technical@techsil.co.uk | +44 (0) 1789 774 244